Supplier of Concrete Mixers in Jharkhand

Concrete mixers are machines used in construction projects to mix cement, aggregates (such as sand or gravel), water, and other additives to create concrete. They play a vital role in ensuring the consistent and homogeneous mixing of these components, which is essential for producing high-quality concrete.

Concrete mixers come in various types and sizes, each designed for specific applications and project requirements. Here are some common types of concrete mixers:

Drum Mixer: This is the most common type of concrete mixer, also known as a tilting drum mixer. It consists of a cylindrical drum that rotates on a horizontal axis. The materials are fed into the drum, and as it rotates, the mixing process takes place. Once the mixing is complete, the drum is tilted to pour out the concrete.

Pan Mixer: A pan mixer features a stationary pan and mixing blades or paddles inside it. The materials are placed in the pan, and the rotating blades mix them thoroughly. Pan mixers are suitable for smaller batches and are often used for precast concrete products.

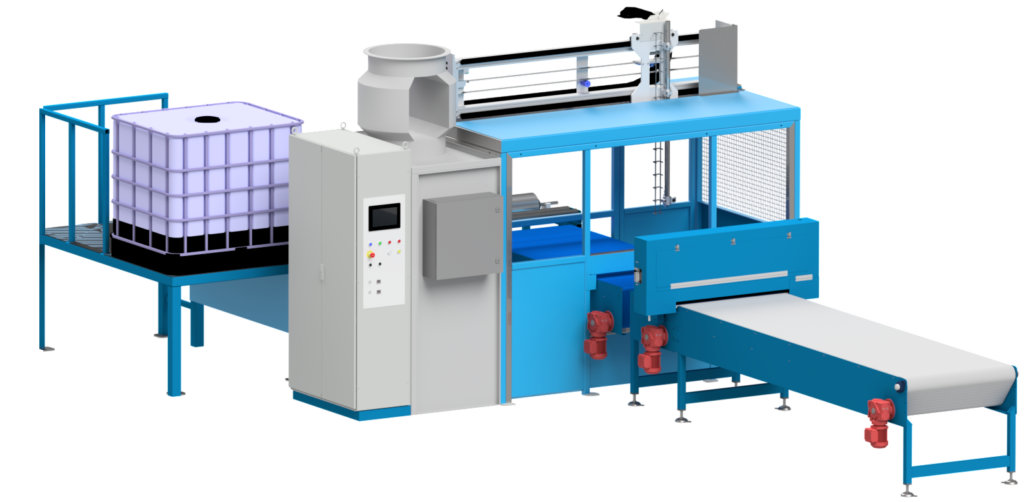

Twin-Shaft Mixer: Twin-shaft mixers have two horizontal shafts with mixing blades rotating in opposite directions. This design ensures intensive mixing, resulting in highly homogeneous and consistent concrete. Twin-shaft mixers are commonly used for large-scale construction projects.

Reversing Drum Mixer: Reversing drum mixers have a rotating drum that can tilt in both directions. This allows for efficient mixing and discharge of concrete. These mixers are suitable for projects requiring multiple batches and are often used in construction sites with limited space.

Vertical Axis Mixer: Vertical axis mixers have a vertical axis with mixing blades that rotate around it. These mixers are compact and ideal for small-scale construction or residential projects.

Concrete mixers can be powered by electricity, diesel, or gasoline engines, depending on the specific model. Some mixers also come with additional features such as built-in water tanks, digital controls, and transportation wheels for easy mobility.

When selecting a concrete mixer, consider factors such as the required mixing capacity, project scale, mobility requirements, and the desired quality of concrete output. It’s crucial to follow proper safety precautions and operating instructions while using concrete mixers to ensure the well-being of operators and the successful completion of construction projects.

We Provide Supplier of Concrete Mixers in Jharkhand Including Jamshedpur, Dhanbad, Ranchi, Deoghar, Phusro, Hazaribag, Giridih, Ramgarh, Medininagar, Chirkunda, Jumri Tilaiya, Madhupur, Gumla, Chatra, Godda, Gumia, Dumka, Garwa, Pakaur.